- Model Town, Panipat, Haryana

info@jindaltex.com

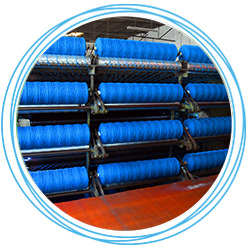

Carding & Spinning Machine

The foundation of the textile industry

Spinning is the first and the most integral part of the textile industry. It is the primary stage where different types of fibres come together and get converted into yarn. The process involves the twisting of drawn-out strands of fibres to form the yarn. In this, ring-spinning is used to spin the yarn. This yarn then travels through many processes for the final product to take shape, for instance, a blanket.

The complex process of spinning can be divided into different stages for easier understanding. The step-by-step process to make short-staple yarn (typically spun from fibres from 0.75 to 2.0 inch) includes - blending, dyeing, opening, carding, pin-drafting, roving and spinning. The spinning frame winds the yarn onto bobbins. It is after this step that the yarn is generally wound to a cone for weaving.

At its state-of-the-art facility, Jindal Woollen has 11 Automated Spinning Lines equipped with the latest technology to produce 600 tonnes of high-quality yarn per month.

Jindal Woollen makes Ring Spun Yarns ranging from 1 Nm to 14 Nm. The facility houses sophisticated machinery and is operated by skilled professionals. This has empowered us to offer custom-made products to our clients, depending upon their style patterns and other requirements.